Mechanical processing

processing

The precision machining sector includes milling, turning and other technologies for the removal or deformation of any type of metal (or plastic materials), such as steel, copper, aluminum, brass and much more and provides a customized design that can adapt to any personal need. FAST Assembler assists and supports the customer in every phase of the process, from the conception to the complete realization of the project.

In this sector, the company relies on the support of constantly updated cutting-edge machinery and qualified professionals: precisely the perfect combination of ingenuity and means, makes Italy one of the most appreciated nations in this field worldwide.

Mechanical

processing

The precision machining sector includes milling, turning and other technologies for the removal or deformation of any type of metal (or plastic materials), such as steel, copper, aluminum, brass and much more and provides a customized design that can adapt to any personal need. FAST Assembler assists and supports the customer in every phase of the process, from the conception to the complete realization of the project.

In this sector, the company relies on the support of constantly updated cutting-edge machinery and qualified professionals: precisely the perfect combination of ingenuity and means, makes Italy one of the most appreciated nations in this field worldwide.

The accuracy

of the mechanics

The precision mechanical processing today guarantees great accuracy and functionality of the finished products, which meet strict quality and safety standards. The possibility of working metals even in infinitesimal parts, in the order of microns, makes the range of products that can be obtained extremely wide, ranging from simple objects to structurally very complex machinery.

Machines and systems for industries, steel boxes for pharmaceutical and electronics companies, parts of automatisms for production lines, are just some of the most common FAST Assembler realizations obtained by mechanical processing.

For any need, pleas do not heistate to contact us!

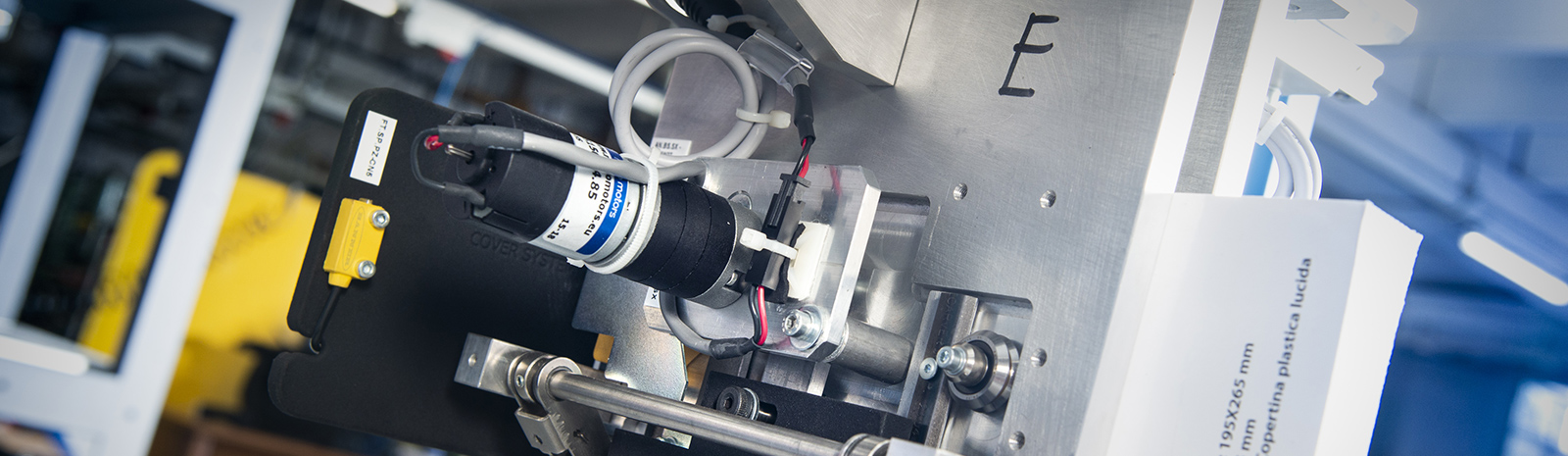

The hight quality of

computerized CNC turning

FAST Assembler has a cutting-edge workshop in terms of technology and machinery, consisting of 5 CNC lathes and 11 cam single-spindle automatic lathes, with bar passage starting from 3 mm up to 50 mm. The workshop is also equipped with CNC lathes for shooting, transfer to 4 and 10 stations, milling machines, tapping machines and grinding machines, for the execution of any type of recovery or recovery according to the customer’s design.

The hight quality of

computerized CNC turning

FAST Assembler has a cutting-edge workshop in terms of technology and machinery, consisting of 5 CNC lathes and 11 cam single-spindle automatic lathes, with bar passage starting from 3 mm up to 50 mm. The workshop is also equipped with CNC lathes for shooting, transfer to 4 and 10 stations, milling machines, tapping machines and grinding machines, for the execution of any type of recovery or recovery according to the customer’s design.

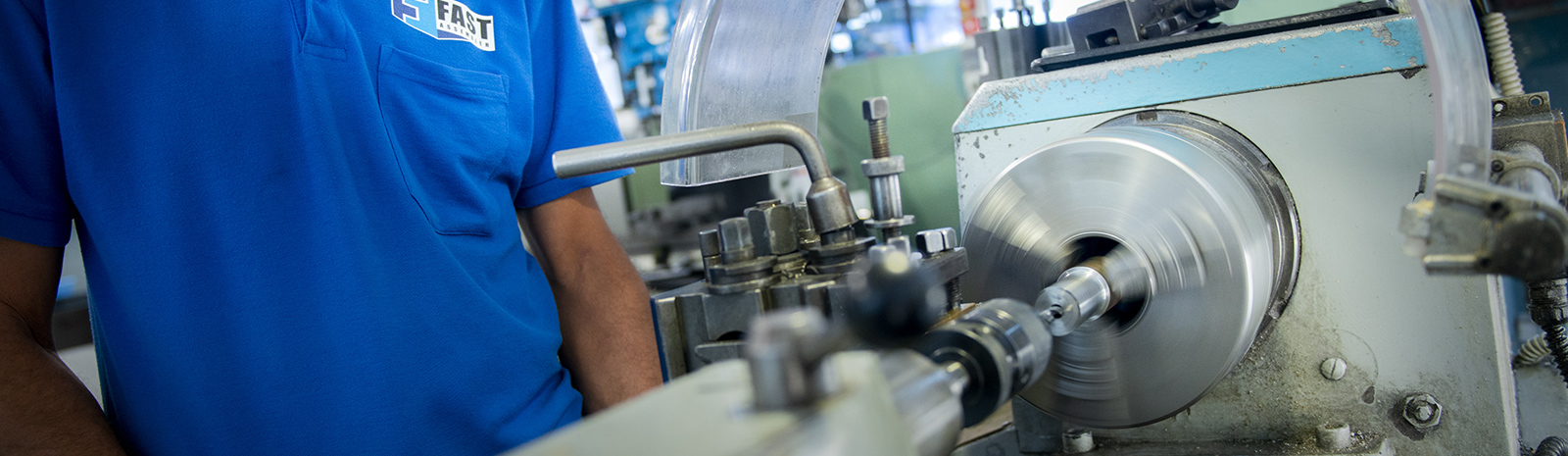

The craftsmanship of

mechanical turnery

CNC machining, however, loses its validity in the creation of small artisan products. Often, in fact, numerically limited production is required, which does not justify the use of complex equipment on which you have to invest a lot of time for programming and which for which a minimum production cannot cover the actual processing costs.

The mechanical turning has therefore never lost its charm at the expense of the CNC turning and is preferred for all those processes in which human intervention can guarantee the optimal quality sought. This form of processing is also necessary for all those cases that go beyond the classic calculation tables used for machining, which require direct intervention by the turner in basing and carrying out the work, a difficult possibility to obtain in the CNC turning. FAST Assembler also deals with this type of processing.